Addition of stabilizers in Sweetened Condensed Creamers formulations

Sweetened Condensed Creamers (SCC) are economical substitutes for traditional Sweetened Condensed Milks (SCM). Typically formulated with non-fat dairy powders, vegetable oils, and sugar, they are usually used as coffee creamers, cake toppings, or in beverages. As mentioned in one of our previous articles, for several years now, the protein content in SCC formulations has been decreasing for economic reasons. Closer to 7.5% in standard SCM, the protein concentration is around 3-5% or even 1.5% in the most economical SCC recipes.

What are the impacts of protein content reduction on the quality of finished products?

Formulating sweetened condensed creamers can be challenging. Indeed, the lack of proteins leads to strong interactions between the oil droplets in the emulsion, known as flocculation. These interactions induce phase separation mechanisms such as creaming, or gel formation, as well as unwanted flow behaviors.

According to our previous studies, to avoid such defects, we advise maintaining a minimum protein content of 3% to guarantee product stability (for more information, see the article Importance of proteins’ concentration in sweetened creamers formulations). Furthermore, as the nature of the proteins is also important, it is essential to maintain a minimum casein content (see the article Importance of casein in sweetened creamers formulations).

Despite these recommendations, there are products on the market with very low protein content. To avoid these defects, the addition of texturizers/stabilizers can be considered

How do the different types of texturizers work?

They work in 2 different ways:

-

-

- Some texturizers adsorb onto oil droplets, thus preventing droplet interactions. For example, carrageenan is known to interact with oil droplet and caseins.

- Others, such as xanthan, increase the viscosity of the continuous phase of emulsions, thus reducing droplets movement and limiting oil-drop interactions [1].

-

These texturizers can be used individually or in combination. Synergy between several stabilizers can reveal additional properties and make it possible to imitate traditional sweetened condensed milks.

How does the addition of texturizing agents influence the quality of Sweetened Condensed Creamers?

The Lactalis Ingredients application team has conducted a study to understand and compare the impact of carrageenan and xanthan on the stability and texture of sweetened condensed creamers.

The texture of these products can be evaluated through 2 complementary parameters:

-

-

- The tendency to form a gel during storage (undesirable defect)

- Flow behavior during use

-

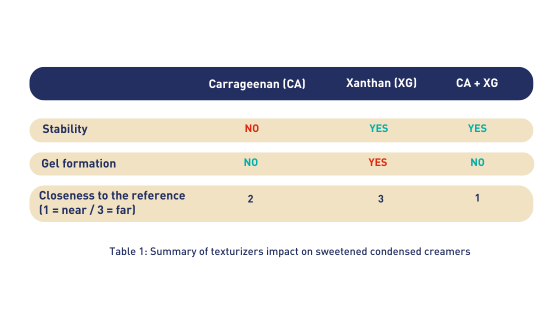

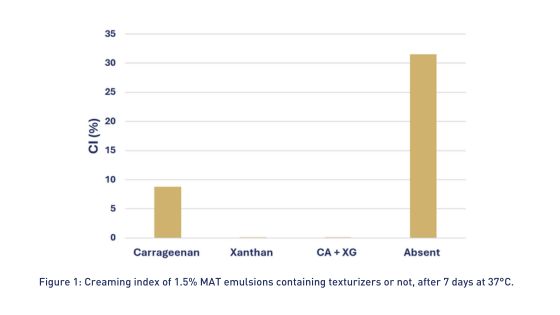

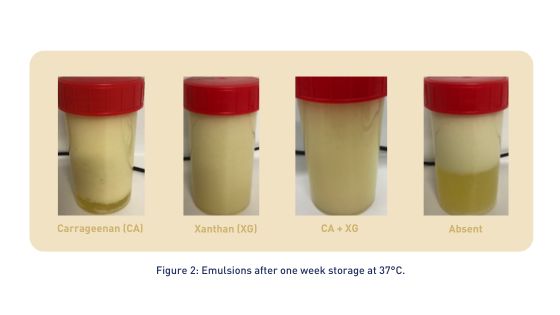

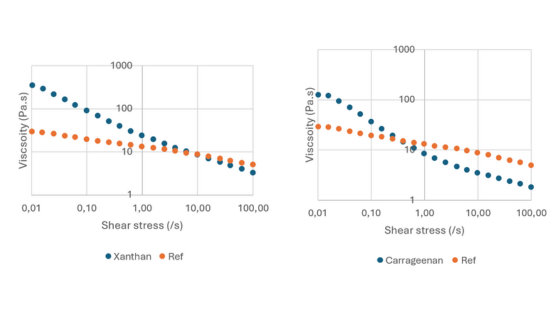

This study shows that the stability of very low-protein products is improved by the addition of xanthan alone or in combination with carrageenan. Indeed, the proportion of serum layer (i.e. the creaming index) is lower in emulsions containing xanthan (see Figures 1 & 2). Xanthan has a significant impact on product texture, increasing viscosity and thus enhancing recipe stability and robustness. However, depending on the concentration used, the addition of xanthan can lead to undesirable gel formation.

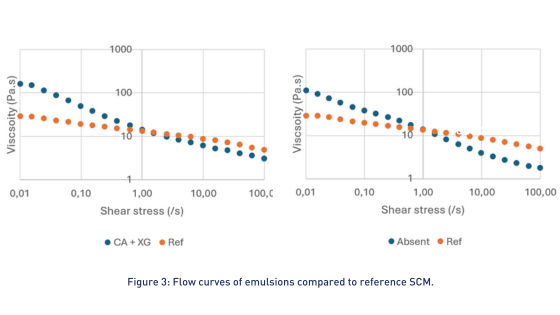

Finally, it is important to highlight that the synergy between the two texturizers is more effective in improving texture than when used individually. Indeed, when carrageenan and xanthan are used together, the flow behavior is closer to the reference product (see Figure 3). What’s more, the combined action of carrageenan and xanthan prevents gel formation, while improving product stability and imitationg as closely as possible the properties of traditional sweetened condensed milk.

Conclusion of the study on texturizers addition in Sweetened Condensed Creamers formulations

We can conclude that the addition of certain texturizers can improve recipe robustness against process and raw material variations.

Moreover, the combined addition of texturizers enables the development of sweetened condensed creamers with specific properties, thus meeting a particular consumer need. In this way, additives can add value to products by conferring special properties.

Our recommendations for the development of stable Sweetened Condensed Creamers formulations

Thanks to our various studies on the subject, we have compiled a list of recommendations to help you formulate high quality and stable SCCs:

-

-

- Maintain a minimum protein content of 3% to avoid texture and stability defects in SCCs.

- Ensure a minimum casein concentration to stabilize the emulsion: our tests enabled us to determine that this threshold corresponds to 0.8 g of casein.

- Add, after trials, stabilizers in formulations containing less than 3% protein

-

We set these recommendations as general guidelines. However, Sweetened Condensed Creamers remain very complex products, with multifactorial technological parameters impacting their structure and stability. As a result, formulations and processes may vary from one producer to another. Nevertheless, the recommendations listed above can be tested and approved under individual conditions.

Any question ? Contact-us !

Sources:

[1] Bryant, C. M., & McClements, D. J. (2000). Influence of xanthan gum on physical characteristics of heat-denatured whey protein solutions and gels. Food Hydrocolloids