Importance of proteins’ concentration in sweetened creamers formulations

Sweetened Condensed Creamers (SCC) are economical substitutes for Sweetened Condensed Milks (SCM), typically formulated with non-fat milk solids, vegetable oil, and sugar. They are mainly used as coffee creamers, cake toppings, or in beverages. The regulation for product declaration as “sweetened condensed creamer” is quite open, offering the opportunity for the manufacturers to develop products with various formulations. Research for cost efficiency can lead for instance to use whey powder or whey permeate to replace skimmed milk powder in the non-fat milk solids.

What are the impacts of these formulation changes on sweetened condensed creamers’ protein composition?

Protein nature in skimmed milk powder, differs from that in whey powder or whey permeate. Among milk proteins, there are two main types: caseins, which precipitate to produce cheese, and whey proteins that tends to form gel when heated. While skimmed milk powder contains ca. 80% caseins and ca. 20% whey proteins, whey powder contains only whey proteins, and permeate powder contains mainly non protein nitrogen. As a result, substituting skimmed milk powder by whey powder or whey permeate in SCC formulation leads to important changes in the protein concentration but also in the protein nature.

How do these protein changes compromise the quality of finished products?

This double modification in the protein composition does impact the texture and stability of sweetened condensed creamers.

Impact on sweetened condensed creamers stability

Recombined sweetened condensed milks following the CODEX standards (i.e. 20% skimmed milk powder in the recipe) holds ca. 7.5% protein. While commercial sweetened condensed creamers have much less protein, with typical values ranging from 3% to 5%, and there is trend to go even further down, with values around 1.5% total nitrogen matter (TNM) in the most economical products.

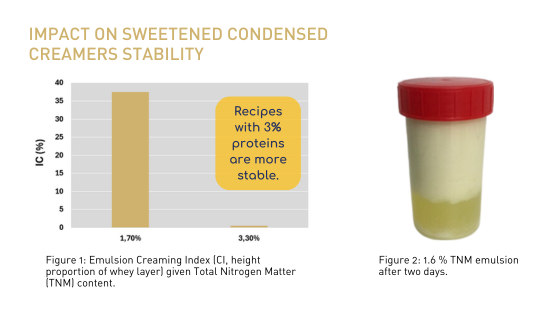

This severe reduction in protein content can affect the stability of the product. Indeed, the fewer proteins in the recipes, the more likely the emulsion in the product is to undergo destabilization, namely through creaming mechanisms. Proteins are required to stabilize the emulsion and prevent oil droplets from merging or interacting and rising to the surface [1]. When comparing recipes around 3% of proteins to those with 1.6%, it becomes evident that recipes with 3% proteins are more stable (see Figures 1 and 2). Indeed, the proportion of the whey layer (i.e. the creaming index) is important in recipes at 1.6% proteins (~30% of the total emulsion height corresponds to whey, see Figure 1) while it was not observable in emulsion at 3% proteins.

Impact on sweetened condensed creamers texture

Texture is a crucial factor in assessing the quality of SCC. The texture can be evaluated through 2 complementary parameters:

-

-

- The tendency to form a gel during storage (gel formation is undesirable).

- The ability to flow during use. Flow behavior must be balanced between ability to flow under low deformation (easy pouring) and a viscosity high enough to reproduce that of sweetened condensed milk.

-

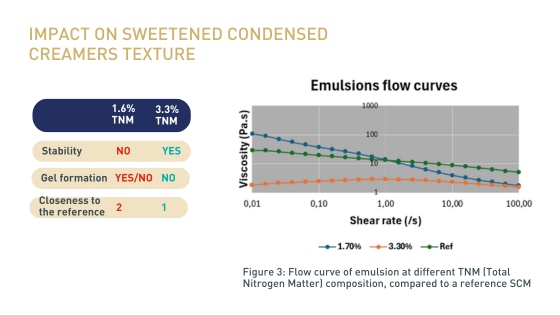

According to our study, the optimum rheological properties were closer in recipes with protein content close to 3%. Recipes with 1.6% protein showed much more deviation compared to a referent SCM. Oil droplets interacted much stronger in the low protein products and may form a gel because of the insufficient protein content.

Conclusion

Further tests showed that destabilization in sweetened condensed creamers occurred when total nitrogen matter was reduced from 2.7% to 2.2%. As a result, the first conclusion that can be drawn from our studies is that keeping total protein content around 2.7% – 3% in sweetened condensed creamer formulation is a safe way to prevent the finished product from texture defects (typically phase separation) and to maintain on-target texture over the shelf life. Moreover, since the nature of the proteins also plays a role, it is important to keep a minimum casein content (for more information, see previous article : Importance of casein in sweetened creamers formulations).

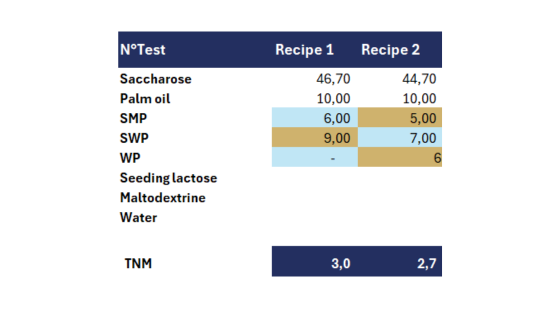

As examples, two formulations containing the recommended protein concentrations are shown below.

If the protein content has to be reduced further (typically around 1.5 to 2.0% protein in the finished product), our tests bring evidence that the recipe will become at risk of destabilizing and gelling. In this type of formulation, the recipe must be complemented with stabilizers to stabilize the structure and to adjust the texture.

This topic will be covered in a future article on Lactalis Ingredients blog, stay tuned.

Any questions ? Contact-us !

Sources:

[1] Dalgleish, D. G. (2004). Food emulsions: their structures and properties. Food emulsions, 4, 1-44